In the market for portable truck scales, wheel weigher scales (also known as wheel weighers) are some of the most versatile truck scales available. In short, wheel weighers are lightweight, portable truck axle scales that are suitable for a wide variety of applications.

Wheel weighers are specifically designed for heavy-duty vehicles working in all types of conditions, including harsh conditions. These weighing systems feature aluminum construction and integrated ramps, making them superior in terms of accuracy and portability. Heavy axle loads and oversized vehicles are not problems when it comes to wheel weighers. These portable truck axle scales come complete with two low-profile weighing pads, easy access ramps, and a digital weighing terminal. It’s these qualities that are helping wheel weigher pave the way for payload management processing.

Low-Profile. Lightweight. Resilient.

Wheel weigher scales or wheel weighers feature an axle scale construction design. They are building from a single piece of aluminum that ensures lightweight for portability and exceptional environmental protection. The fully waterproof weighing pads are well-designed and constructed to perform well in any environmental condition, making it easy to weigh your vehicle anywhere.

All wheel weighers come with lightweight removable ramps that allow for simple access to the scale pads and also provide a bright visual alert to the drivers. Installing and removing the axle scale rum is extremely simple. They feature low-profile design that makes it easy for a vehicle to enter easily and exit the scale pads. The low profile also assists in providing extremely accurate results even when the system is in motion.

Portability That Doesn’t Sacrifice Performance

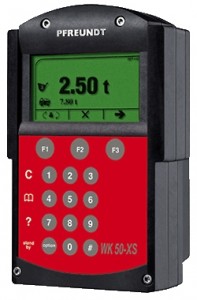

Most wheel weigher scales include an integrated weighing terminals, which features a self-contained digital printer with a durable battery and internal receipt printer. This means that the lightweight weighers were designed for optimal portability. The weighing terminal gives the user enough data, which span from real-time weight measurements to axle type comparisons. The integrated weighing terminal is easy to install on the wheel weigher scales. The ticket printer is a very important resource that provides tangible mean of communicating weight metrics to users.

Most wheel weigher scales include an integrated weighing terminals, which features a self-contained digital printer with a durable battery and internal receipt printer. This means that the lightweight weighers were designed for optimal portability. The weighing terminal gives the user enough data, which span from real-time weight measurements to axle type comparisons. The integrated weighing terminal is easy to install on the wheel weigher scales. The ticket printer is a very important resource that provides tangible mean of communicating weight metrics to users.

OTR Wheel weigher scales, which are a type of wheel weigher scales/wheel weighers are also available in the market. This type of scales includes oversized construction that can accommodate super capacity while featuring portable wheel load construction. These types of wheel loader scales make it easy to weigh off-road vehicles anywhere. The Wheel Weighers scales are the best for applications such as mining, freight, farming and shipping.

Capable of High-Capacity Weighing Operations

Unlike most other types of truck axle scales, which accommodate limited capacity based on tire and size, the Wheel weigher scales can accommodate even the most robust mining trucks as well as hauling vehicles. They are designed to handle articulated trucks and much other variety of heavy-duty trucks, which make them the best industry choice for high-capacity and high volume weighing.

Last but not least, most types of wheel weighers comes with portable carry case, which is ideal for protecting the scale pads especially during transportation or storage. The compact carry case is well designed to protect the device while maintaining its key feature of portability.

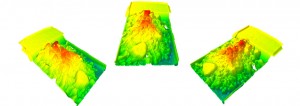

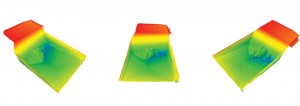

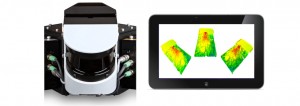

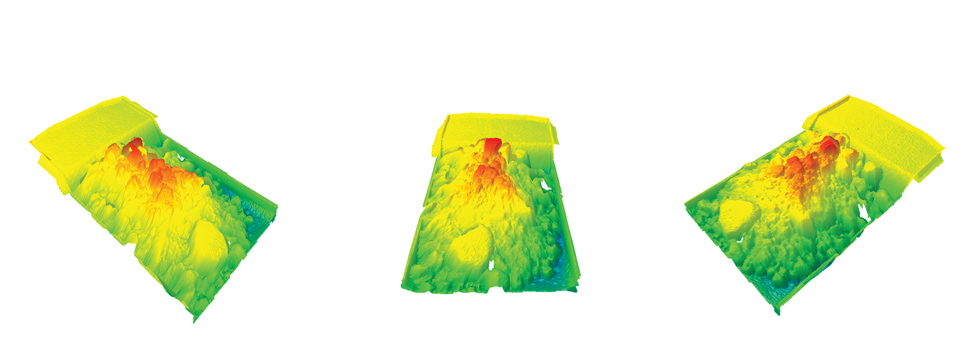

Weighing technology is dynamic. There are new inventions and improvements in weighing systems being released each year. Today, most weighing systems and truck scales produced offer greater levels of efficiency and accuracy. In fact, some of these “weighing systems” offer revolutionary features and capabilities, such as 3D laser scanning technology and in-motion weighing capabilities.

Weighing technology is dynamic. There are new inventions and improvements in weighing systems being released each year. Today, most weighing systems and truck scales produced offer greater levels of efficiency and accuracy. In fact, some of these “weighing systems” offer revolutionary features and capabilities, such as 3D laser scanning technology and in-motion weighing capabilities.

On-board weighing systems and equipment help to ensure effective and accurate weight measurement for farmers, transporters, miners, construction companies, and other industrial-based businesses. These on-board scales are installable in many vehicle types depending on the client’s’ needs.

On-board weighing systems and equipment help to ensure effective and accurate weight measurement for farmers, transporters, miners, construction companies, and other industrial-based businesses. These on-board scales are installable in many vehicle types depending on the client’s’ needs.